Strong business relationships don’t feel transactional – they feel like working with your own team. McGough aims to make every construction project feel like a partnership, and it works so well it’s hard to imagine working any other way.

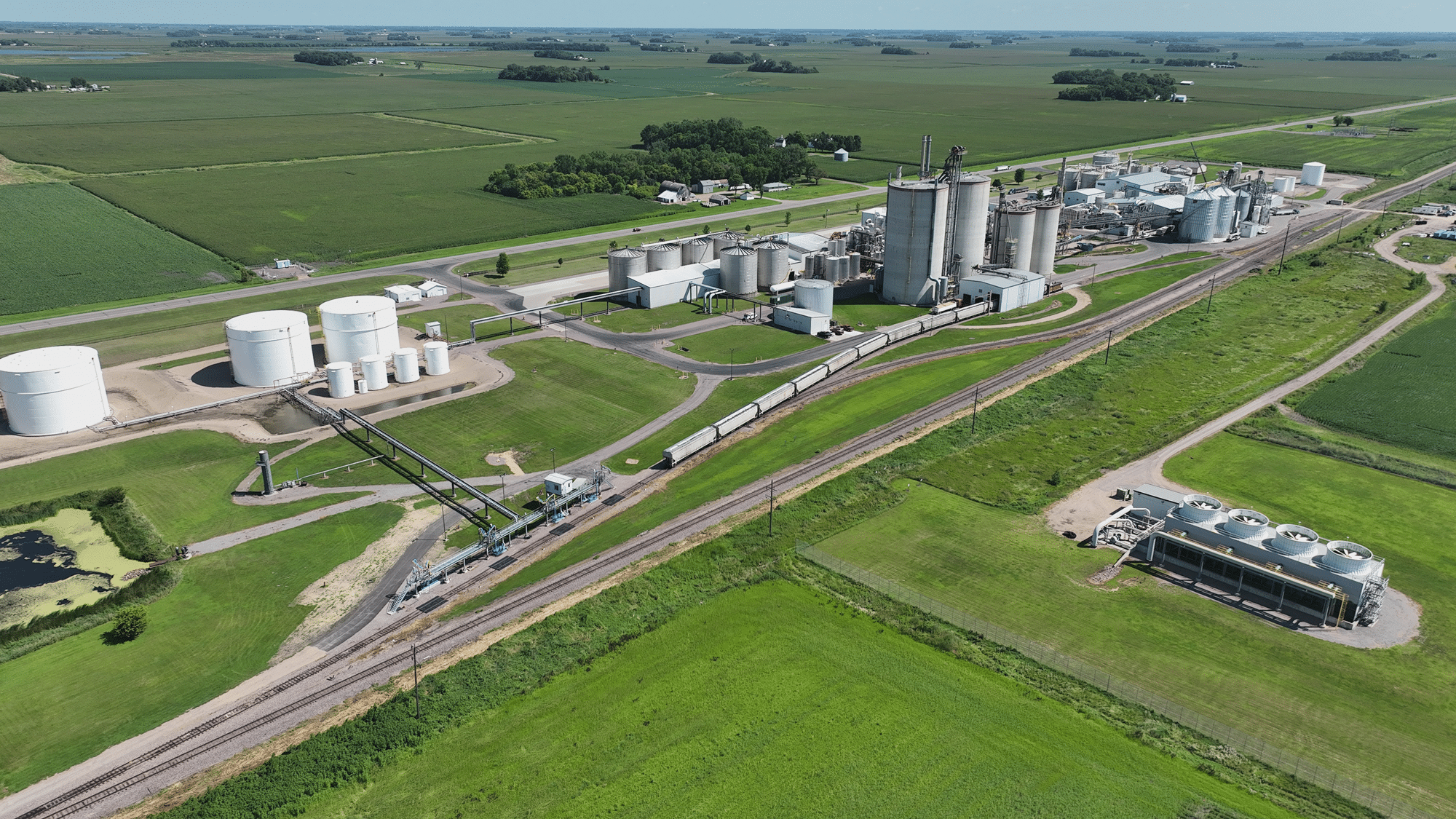

For over two decades, McGough’s industrial team has been developing and executing projects for Heartland Corn Products in Winthrop, MN, on its ethanol refinery and corn processing facility. McGough has an almost continuous presence on the site and offers both consultative advice and construction services to help Heartland realize its vision and growth strategy.

“Flexibility makes the relationship work,” said Tom Paitrick, CEO of Heartland Corn Products. “McGough understands how we make money and how they can positively impact that. Our partnership works because for either of us to be successful, both of us do.”

Nathan McAlpine, director for industrial operations at McGough, agreed. “They’re one of our best partners,” he said. “We try and operate with them like they’re part of McGough, and they look at us like we’re part of Heartland.”

A Record of Continuous Growth

Founded in 1992, Heartland Corn Products is a cooperative owned by about 920 farmers with the mission of adding value to every bushel of corn processed, producing ethanol as a fuel additive, distiller’s corn oil and dried distiller’s grain.

First operational in 1995 with a 10 million gallon per year (MMGPY) capacity, Heartland was one of the first commercial-scale ethanol plants in the US. “Today we’re operating at near 160 million gallons per year,” Paitrick said. “We’ve grown by a multiple of over 15 times. McGough was there throughout [since 2000] and really helped make that happen.”

As a cooperative, Paitrick noted, Heartland needs to serve its members, and can’t pause production or wait for optimal market conditions to make additions or improvements to the facility. “We need to continue operations 365 days a year, and McGough has been instrumental in helping us to maintain that.”

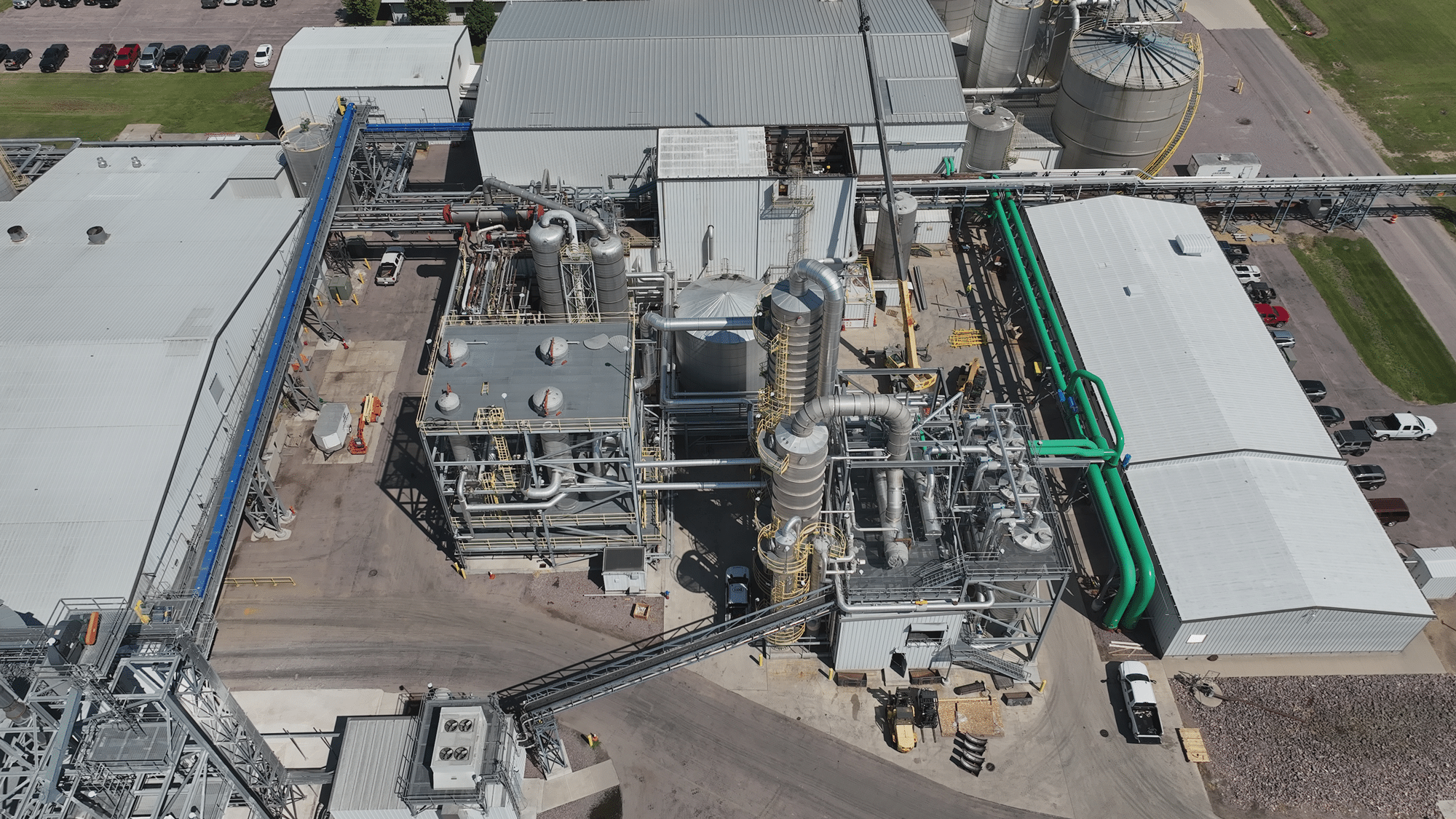

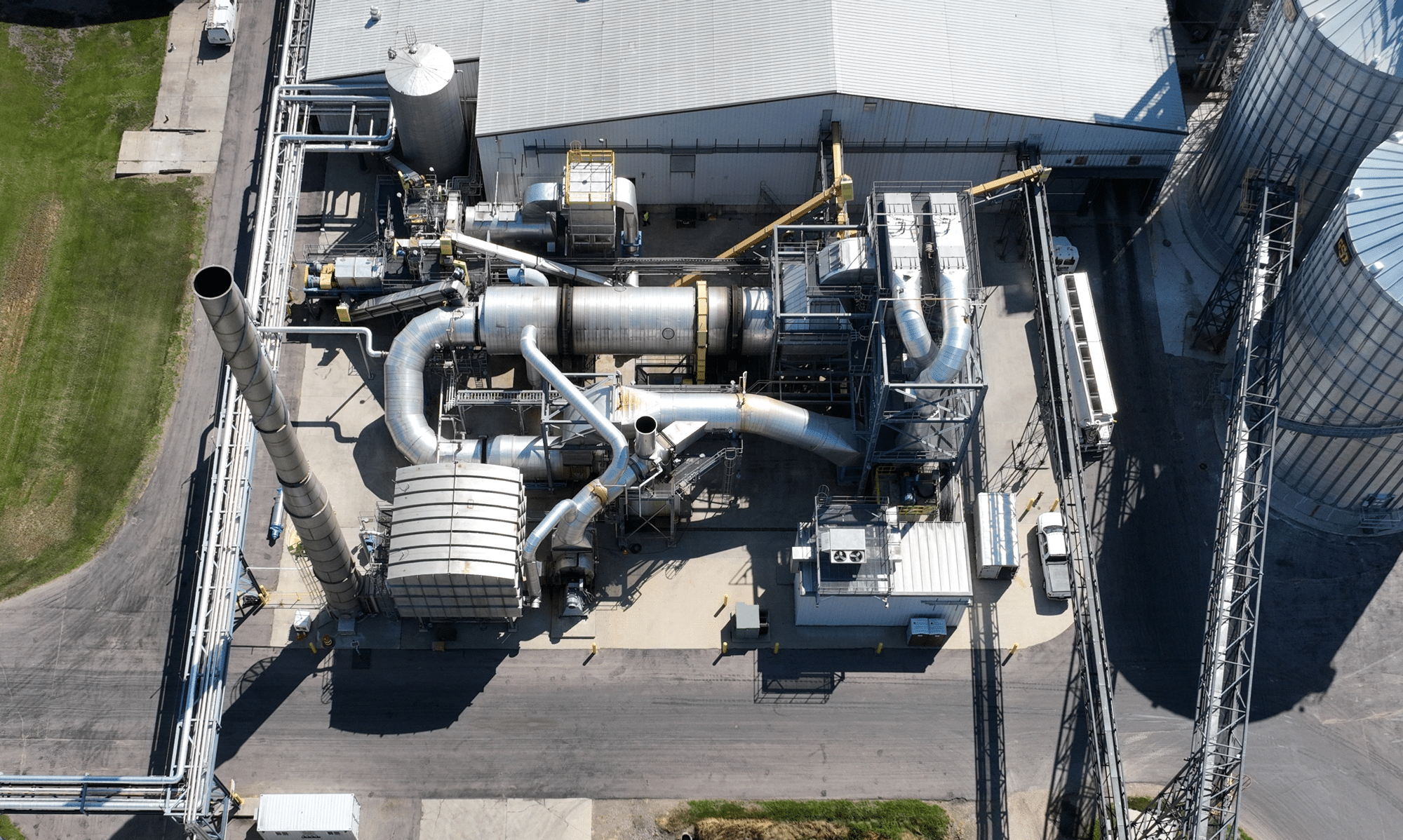

Heartland’s facility requires significant expertise, scale and precision. Some of the more notable additions and improvements completed by McGough have included:

And that doesn’t include scores of other improvements and enhancements to the site.

Going Beyond the Norm: A Win-Win Delivery Model

Over the years, McGough and Heartland have developed a unique model rooted in trust and transparency. McGough maintains a continuous presence on site, making it easy for Heartland to loop in construction expertise while planning projects. Meanwhile, the delivery model used allows Heartland to remain engaged throughout project execution.

“We have a lot of trust in what McGough is doing, and trust that they are looking out for our best benefit,” Paitrick said. “The model really provides the most value for both parties. We’re able to get a very custom delivered product, and McGough is still there to help us mitigate risk so we can move forward with some of the larger projects.”

Being on site and part of the team also lets McGough help with the unexpected. One exceptionally harsh winter, ice buildup collapsed a building roof despite efforts to clear it. McGough was there to make an immediate assessment and assemble a team to recover equipment, demo the damaged structure, rebuild and reinstall, all while rerouting crucial systems to keep the plant up and running.

“I think they like that they can throw stuff at us and say ‘How can you help?’” said McAlpine. “We do whatever we can to get it done as fast as we can, and with the same quality we deliver for all our clients.”

Helping Heartland Scale Up – Today and In the Future

The relationship will continue with significant upgrades and additions in the years to come. There’s a second combined heat and power turbine and a number of other plant modifications that Paitrick said will help reduce bottlenecks and increase efficiency. The two plants at the site are permitted to produce up to 180 MMGPY, so Heartland can continue to scale up in the near term.

Longer term, Paitrick said, the plant hopes to secure a permit to expand to 240 million gallons per year and add carbon dioxide capture and liquefaction on the site – projects he expects McGough will help execute.

Whatever the future holds, Paitrick knows McGough will help add to the expertise of his small but experienced staff as if they were true co-workers. “For a lot of contractors, the objective is to make money and deliver the bare minimum that they need to,” he said. “We don’t need to worry about that. With McGough, we know that at the end of the day we’re going to get the product and the quality that we’re looking for.”